Fasteners are an essential part of any machinery, tool, or equipment. They keep the various parts together, ensuring the overall structure remains intact, even under extreme conditions. And when it comes to fasteners required to withstand high temperatures and extreme pressure, Inconel 718 is a name that quickly comes to mind.

JIS NCF 718 Fasteners, Alloy 718 Fasteners, Inconel 718 Industrial Fasteners, Nickel Alloy 718 Fasteners, Inconel 718 Screws, 718 Inconel Fasteners, Inconel® Alloy 718 Fasteners, Inconel Alloy 718 Nuts, Inconel 718 Fasteners Manufacturers in India.

Inconel 718 Fasteners are available in different types, each designed to suit specific applications. The most common Inconel 718 fasteners are bolts, nuts, screws, washers, and studs. The bolts and studs hold two or more components together, while nuts provide extra grip to the assembly. Screws attach two or more parts where no through-hole is available. The washers distribute the load evenly on the bolt head or nut and the surface it's attached to.

Inconel Alloy 718 Washers, Alloy 718 Bolts, Alloy Din 2.4668 Fasteners, Nickel Alloy 718 Fasteners, UNS N07718 Fasteners, 718 Inconel Screw, Inconel Alloy 718 Fasteners, Inconel® Alloy 718 Fasteners Manufacturer, Inconel 718 Fasteners Manufacturers In Mumbai.

Inconel 718 fasteners find extensive use in the aerospace and defence industries, particularly in jet engines, gas turbines, and rocket motors. They are also used in oil and gas exploration equipment, as well as in high-temperature processing plants and cryogenic systems. Inconel 718 is known for its corrosion resistance, high-temperature strength, and excellent fatigue life, making it a go-to choice for some of the most demanding applications.

Inconel 718 fasteners are used for various purposes, including securing aircraft and spacecraft components, attaching heat shields, and holding fuel systems. They are also used in downhole drilling and completion tools for oil and gas exploration. The high-temperature durability of Inconel 718 fasteners is a significant advantage in these applications, making them suitable for use in extreme temperatures and harsh environments.

The primary benefit of Inconel 718 fasteners is their ability to withstand high temperatures without losing strength or corroding. That makes them ideal for high-temperature applications like aerospace, oil and gas processing, and power generation. The fatigue resistance of the alloy also ensures that the fasteners don't fail even under high-stress conditions. Besides, Inconel 718 fasteners' corrosion resistance ensures they can withstand exposure to saltwater, acid, and other corrosive substances, making them ideal for use in marine environments. Inconel 718 fasteners are a reliable and durable solution for applications that require high strength and corrosion resistance.

Inconel 718 Bolts and Nuts Specification

| Standard | ASTM B637 / ASME SB637 |

| Bolt / Screw Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Nuts Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Washers Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Machine Screws Size | M1.6 – M12 |

| Self Tapping Screw Size | No.2 – No. 14 |

| Length | 3 mm to 200 mm |

| Threads | UNF, BSW, BSF, METRIC, UNC, or as required |

| Fasteners |

|

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Raw materials Source | JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin,etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production Process | M24-M100: hot forging , M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Types | Bolts, Nuts, Stud Bolts, Washers, Threaded Rod, Anchor Fasteners, Eye Bolt, Stud, Cotter Pin, Socket Screw, Fine Fasteners & Spares, Foundation Fasteners, Hexagon Castle Nuts, Hexagon Domed Cap Bolts, Hexagon Thin Nuts etc. |

Inconel 718 Fasteners Price List

| Price List of Inconel 718 Fasteners | Inconel Alloy 718 Fasteners Price in India (INR) | Alloy 718 Fasteners Price in USD | Nickel Alloy 718 Fasteners Price in UAE (Dirham) |

|---|---|---|---|

| Nickel Alloy 718 Fasteners Price List | ₹ 3,636 | $ 43.33 USD | 135.17 AED |

| Inconel® Alloy 718 Bolts Price List | ₹ 4,678 | $ 38.45 USD | 35.27 AED |

| Alloy 718 Nut Bolt Price Per Kg | ₹ 2,337 | $ 36.00 USD | 65.10 AED |

| M16 5/8inch Inconel 718 Hex Head Bolt Price List | ₹ 2,334 | $ 46.21 USD | 164.27 AED |

| Price of Inconel 718 Stud Bolt | ₹ 6,343 | $ 36.70 USD | 166.71 AED |

| Inconel 718 Screws Price | ₹ 2,228 | $ 23.72 USD | 96.45 AED |

| 718 Inconel Nut Bolt Price List | ₹ 2,375 | $ 27.35 USD | 76.73 AED |

| M8 Inconel 718 Hex Flange Nut Price | ₹ 2,349 | $ 29.19 USD | 46.76 AED |

| Inconel 718 Hex Bolt Price List | ₹ 4,442 | $ 247.32 USD | 468.50 AED |

Inconel Alloy 718 Fasteners Technical Data Sheet

Inconel 718 Fasteners Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Inconel 718 | 2.4668 | N07718 |

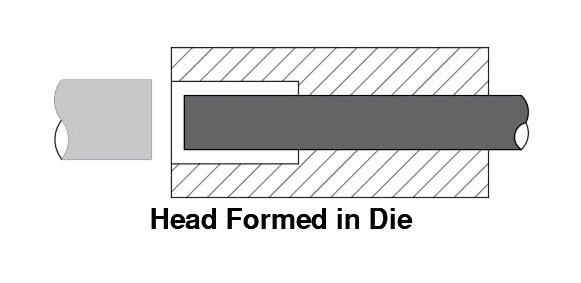

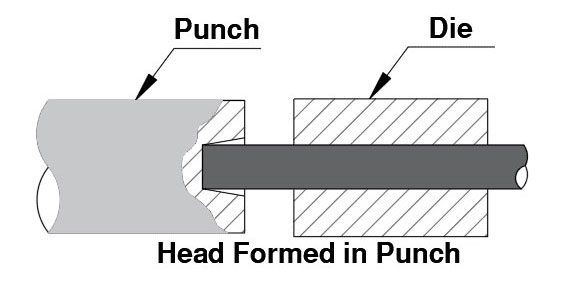

718 Inconel Fasteners Manufacturing Process

Common Types Of Inconel 718 Fasteners

Inconel® Alloy 718 Bolts

718 Inconel Nuts

Inconel Alloy 718 Steel Screw

Alloy 718 Washer

Nickel Alloy 718 Stud Bolts

Inconel 718 Anchor Bolts

Other Type 718 Inconel Fasteners

- Alloy 718 Anchor Fasteners

- Inconel Alloy 718 Fasteners Supplier

- Inconel 718 Fasteners Suppliers in India

- Nickel Alloy 718 Fasteners Manufacturers in Mumbai

- 718 Inconel Industrial Fasteners Distributors

- Inconel 718 Fasteners Manufacturers in India

- ASTM B637 Inconel 718 Fasteners

- Inconel® Alloy 718 Anchor Fasteners

- M10 Inconel 718 Bolts

- Inconel Alloy 718 Fasteners Stock

- UNS N07718 Washers

- Inconel 718 Fasteners Manufacturers in Mumbai

- 718 Inconel Heavy Hex Nuts

- 718 Inconel Structural Bolts

- M12 Inconel 718 Nuts

- Inconel 718 Fasteners Suppliers in Mumbai

- Nickel Alloy 718 U Bolts

- Inconel 718 Heavy Hex Bolts

- 718 Inconel Stud Bolts

- Self Tapping Inconel 718 Screws

- Inconel 718 Hex Nuts

- Inconel Alloy 718 Fasteners Manufacturers in India

- Alloy 718 Fasteners Exporters

- Inconel Alloy 718 Fasteners Suppliers in Mumbai

- M6 Inconel 718 Washers

- Inconel 2.4668 Hex Bolt

- UNS N07718 Eye Bolts

- Alloy 718 Fasteners Suppliers in India

- Inconel® Alloy 718 Lug Nuts

- Nickel Alloy 718 Coupling Nuts

Inconel 718 Fasteners Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | - | 50.00 - 55.00 | 17.00 - 21.00 |

Alloy 718 Fasteners Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |