When it comes to high-temperature applications where strength and corrosion resistance are essential, few materials surpass Inconel 601. With exceptional mechanical properties, this material has found its way into numerous industrial applications. Inconel 601 fasteners are one of the most popular products made from this material.

Inconel 601 Fasteners, Inconel® Alloy 601 Fasteners, 601 Inconel Fasteners, Inconel Alloy 601 Nuts, Inconel 601 Bolts, Inconel 601 Screws, Nickel Alloy 601 Fasteners, Inconel 601 Fasteners Manufacturers in India.

Inconel 601 has a high melting point, making it an excellent material for high-temperature applications. Different types of Inconel 601 Fasteners are suitable for a wide range of applications. The most commonly used types include Inconel 601 bolts, nuts, washers, and screws. These fasteners have unique properties that make them ideal for specific functions or applications. Inconel 601 bolts are commonly used in the aerospace, automotive, and chemical processing industries.

Inconel Alloy 601 Washers, Inconel Alloy 601 Fasteners, Inconel UNS N06601 Fastener, 601 Inconel Screw, Inconel® Alloy 601 Fasteners Manufacturer, Nickel Alloy 601 Fasteners, ASTM B166 N06601 Fasteners, Inconel 601 Bolts, Inconel 601 Fasteners Manufacturers In Mumbai.

Applications that require high-temperature resistance, such as furnace fixtures, heat exchangers, and gas turbines, are where Inconel 601 fasteners shine. These fasteners are highly resistant to corrosion, making them ideal for harsh environments where ordinary fasteners would quickly degrade. The aerospace and automotive industries widely use Inconel 601 bolts, thanks to their ability to withstand high operating temperatures.

Inconel 601 fasteners have many uses, mainly in high-temperature environments. These fasteners are highly resistant to carburization and oxidation, making them perfect for petrochemical, chemical processing, and power generation plants. These industries use Inconel 601 bolts and nuts in pumps, heat exchangers, and furnace fixtures. The aerospace and automotive industries also use these fasteners in engine applications.

Inconel 601 fasteners have several benefits, including superior resistance to corrosion, high-temperature strength, and oxidation resistance. These fasteners can maintain strength at temperatures up to 2200°F, making them ideal for high-temperature applications. In addition to their superior strength, Inconel 601 fasteners are highly resistant to carburization and oxidation, even in harsh environments. These attributes make Inconel 601 fasteners a popular choice in various industries.

Inconel 601 fasteners are popular for applications requiring high-temperature resistance and superior mechanical strength. These fasteners are highly resistant to carburization and oxidation and maintain their strength at temperatures up to 2200°F. They are widely used in aerospace, automotive, and chemical processing industries, where high-temperature resistance is essential. Inconel 601 fasteners offer superior corrosion resistance and a prolonged lifespan, making them a reliable choice for harsh environments.

Inconel 601 Bolts and Nuts Specification

| Standard | ASTM B166 / ASME SB166 |

| Bolt / Screw Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Nuts Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Washers Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Machine Screws Size | M1.6 – M12 |

| Self Tapping Screw Size | No.2 – No. 14 |

| Length | 3 mm to 200 mm |

| Threads | UNF, BSW, BSF, METRIC, UNC, or as required |

| Fasteners |

|

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Raw materials Source | JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin,etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production Process | M24-M100: hot forging , M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Types | Bolts, Nuts, Stud Bolts, Washers, Threaded Rod, Anchor Fasteners, Eye Bolt, Stud, Cotter Pin, Socket Screw, Fine Fasteners & Spares, Foundation Fasteners, Hexagon Castle Nuts, Hexagon Domed Cap Bolts, Hexagon Thin Nuts etc. |

Inconel 601 Fasteners Price List

| Price List of Inconel 601 Fasteners | Inconel Alloy 601 Fasteners Price in India (INR) | Inconel 601 Fasteners Price in USD | Nickel Alloy 601 Fasteners Price in UAE (Dirham) |

|---|---|---|---|

| Price of Inconel 601 Stud Bolt | ₹ 3,343 | $ 36.70 USD | 126.71 AED |

| Nickel Alloy 601 Fasteners Price List | ₹ 3,536 | $ 44.33 USD | 155.17 AED |

| Inconel® Alloy 601 Bolts Price List | ₹ 1,678 | $ 38.45 USD | 57.27 AED |

| Inconel 601 Hex Bolt Price List | ₹ 4,442 | $ 247.32 USD | 468.50 AED |

| M8 Inconel 601 Hex Flange Nut Price | ₹ 1,249 | $ 15.19 USD | 46.76 AED |

| 601 Inconel Nut Bolt Price List | ₹ 1,375 | $ 29.35 USD | 79.73 AED |

| M16 5/8inch Inconel 601 Hex Head Bolt Price List | ₹ 2,334 | $ 26.21 USD | 104.27 AED |

| Inconel 601 Screws Price | ₹ 2,228 | $ 23.72 USD | 96.45 AED |

| Inconel 601 Nut Bolt Price Per Kg | ₹ 1,337 | $ 16.00 USD | 66.10 AED |

Inconel Alloy 601 Fasteners Technical Data Sheet

Inconel 601 Fasteners Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| Inconel Alloy 601 | N06601 | 2.4851 | NCF 601 | NC23FeA | NA 49 | XH60BT | NiCr23Fe |

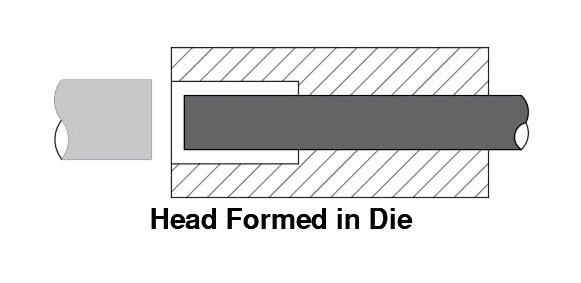

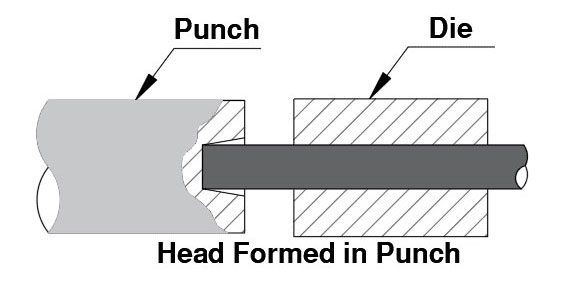

601 Inconel Fasteners Manufacturing Process

Common Types Of Inconel 601 Fasteners

Inconel® Alloy 601 Bolts

601 Inconel Nuts

Inconel Alloy 601 Steel Screw

Inconel 601 Washer

Nickel Alloy 601 Stud Bolts

Inconel 601 Anchor Bolts

Other Type 601 Inconel Fasteners

- 601 Inconel Heavy Hex Nuts

- Inconel® Alloy 601 Anchor Fasteners

- Inconel 601 Fasteners Manufacturers in Mumbai

- 601 Inconel Structural Bolts

- UNS N06601 Washers

- ASTM B166 Inconel 601 Fasteners

- 601 Inconel Industrial Fasteners Distributors

- Inconel Alloy 601 Fasteners Supplier

- M10 Inconel 601 Bolts

- Inconel 601 Fasteners Manufacturers in India

- M12 Inconel 601 Nuts

- Nickel Alloy 601 Fasteners Manufacturers in Mumbai

- Inconel 601 Fasteners Suppliers in India

- Inconel 601 Anchor Fasteners

- Inconel Alloy 601 Fasteners Stock

- M6 Inconel 601 Washers

- Nickel Alloy 601 Coupling Nuts

- Inconel Alloy 601 Fasteners Suppliers in Mumbai

- 601 Inconel Stud Bolts

- Inconel® Alloy 601 Lug Nuts

- Inconel Alloy 601 Fasteners Manufacturers in India

- Inconel 601 Hex Nuts

- UNS N06601 Eye Bolts

- Inconel 601 Heavy Hex Bolts

- Inconel 601 Fasteners Suppliers in India

- Inconel 601 Fasteners Exporters

- Inconel 2.4851 Hex Bolt

- Nickel Alloy 601 U Bolts

- Self Tapping Inconel 601 Screws

- Inconel 601 Fasteners Suppliers in Mumbai

Inconel 601 Fasteners Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Inconel 601 Fasteners Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |