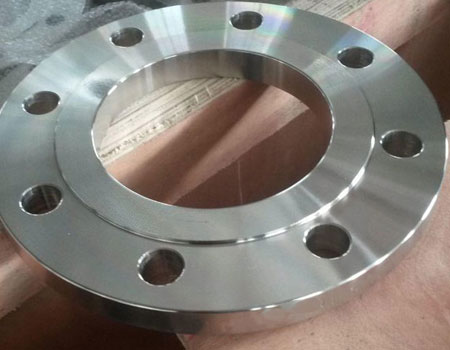

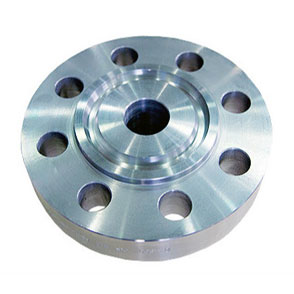

Dhanratan Steel Industries offers a wide selection of Inconel 601 flanges. They are known for their special features, such as superior finishes. For corrosion resistance and ease of installation, our Inconel 601 Slip On Raised Flanges (UNS N06601) are widely available for radian pipes. Spiral Annealed Pipe, Super Steam—used to support heater pipes. Other users are attracted to Inconel 601 threaded flanges because of their excellent resistance to hydraulic corrosion and outstanding mechanical strength.

Our Inconel 601 Weld Neck Raised Flanges are produced using conventional manufacturing techniques to ensure high quality and reliability. For optimal oxidation resistance, Inconel 601 Blind Flanges should be welded using matching composition 601 alloy GTAW wire. The Inconel 601 Socket Weld Flanges develop a tightly adherent oxide scale that resists spalling, even under severe thermal cycling conditions.

601 Inconel Pipe Flanges, Inconel 601 Slip On Flanges, Inconel 601 Spectacle Blind Flanges, Inconel 601 Long weld neck, Inconel 601 Long Weld Neck Flanges, Inconel 601 Lap Joint Flanges Manufacturers in India.

Inconel 601 Ring Joint Type Flanges find extensive use in thermal processing equipment, including fixtures, baskets, trays, radiant tubes, flame shields, muffles, retorts, woven wire conveyors, electrical resistance heating wires, and burner nozzles.

Inconel 601 Reducing Flange, Inconel 601 Spectacle Blind Flanges, Inconel 601 Nippolet Flanges, Inconel 601 Plate flange, Inconel 601 RTJ Flanges, Inconel 601 Forged Flanges Manufacturers in India.

Moreover, our Inconel 601 Spectacle blind flanges are important in various industries. including pollution control aerospace, which is used to ignite jet engines and electricity production As a worldwide exporter of Inconel 601 flanges, we guarantee that our Inconel 601 Long Weld Neck products, including flanges, provide excellent resistance to carburization and carbonitridizing conditions.

Also, nickel has features offering high resistance to carburization that prevent metallurgical changes and afford excellent creep rupture strength to our Inconel 601 Nipo Flanges. Inconel 601 Lap Joint Flanges products are available in various sizes and shapes as per the customer's requirements.

Inconel 601 Flanges Specification

| Standard | ASTM B564 / ASME SB564 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flange Size Chart | 1/2" (15 NB) to 48" (1200NB), DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Flange Connection / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove, Flange Pipe. |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Types of Flanges | Threaded / Screwed / Forged / Plate |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Test Of Flange | Direct-reading Spectrograph, Ultrasonic flaw detector, Magnetic particle detector, X-ray detector, Hydrostatic testing machine. |

| Production technique Used | Heat treated, Forged and Machined |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc. |

| Test Certificates | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc |

Inconel 601 Pipe Flanges Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

Inconel Alloy 601 Flanges Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Inconel Alloy 601 Flange Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

| Price List of Inconel 601 Flanges | Inconel Alloy 601 Flange Price in India (INR) | Inconel 601 Flanges Price in USD | Inconel Alloy 601 Flanges Price in UAE (Dirham) |

|---|---|---|---|

| Inconel 601 Threaded Flanges Price | ₹ 1468 | $ 15.62 USD | 52.60 AED |

| Price of Inconel 601 Flanges | ₹ 1150 | $ 20.78 USD | 70.50 AED |

| Inconel Alloy 601 Flanges Price List | ₹ 1454 | $ 22.60 USD | 78.50 AED |

| Inconel 601 Flange Price | ₹ 1304 | $ 11.59 USD | 60.52 AED |

| Inconel Alloy 601 Raised Face Blind Flange | ₹ 1357 | $ 10.53 USD | 37.17 AED |

| Inconel Alloy 601 Flanges Price | ₹ 1200 | $ 11.24 USD | 28.50 AED |

| Inconel Alloy 601 Flange Price Per Kg | ₹ 850 | $ 10.69 USD | 50.02 AED |

| Inconel Alloy 601 Flange Price List India | ₹ 1384 | $ 29.50 USD | 112.00 AED |

Inconel Alloy 601 Weld Neck Flanges

Inconel 601 Blind Flanges

UNS N06601 Socket Weld Flanges

Inconel Alloy 601 Slip-on Flanges

Inconel 601 RTJ Flange

Inconel Alloy 601 Forged Flanges

Inconel 601 Lap Joint Flanges

Inconel Alloy 601 Threaded Flanges

Inconel Alloy 601 Spectacle Blind Flange

- Inconel Alloy 601 Socket weld Flanges

- UNS N06601 Flanges

- Inconel 601 Lap Joint Flanges

- Inconel Alloy 601 Flanges Manufacturers in India

- UNS N06601 Long Weld Neck Flanges

- Inconel 601 Square Flanges

- Inconel 601 Forged Flanges

- Inconel 601 Reducing Flanges

- ASTM B564 Inconel Alloy 601 Plate Flange

- Inconel 601 Square Flanges

- Inconel 601 Flat Flange

- Inconel Alloy 601 Threaded Flanges

- Inconel 601 Socket Weld Flanges

- Inconel Alloy 601 Flange Dimensions

- Inconel 601 Flanges Manufacturer in Mumbai

- Inconel 601 Flat Face Flange

- Inconel 601 Weld Neck Flanges

- Inconel 601 Flanges Suppliers in India

- Inconel 2.4851 Raised Face Flanges

- Inconel® Alloy 601 Reducing Flanges

- Inconel 601 Slip on Flanges

- Inconel 2.4851 Plate Flanges

- UNS N06601 Plate Flanges

- 2.4851 Pipe Flanges

- Inconel Alloy 601 Industrial Flanges

- Inconel 601 Orifice Flanges

- B564 UNS N06601 Blind Flanges

- Inconel Alloy 601 Flange Suppliers in India

- Inconel 601 Ring Type Joint Flanges

- Inconel Alloy 601 Lapped Joint Flanges

- Inconel Alloy 601 Pipe Flanges

- Inconel Alloy 601 Flanges Suppliers in Mumbai

- Inconel 601 Flanges Suppliers in Mumbai

- ASME SB564 Inconel Alloy 601 Pipe Flange

- ANSI B16.5 Inconel 601 Pipe Flanges

- Inconel 601 Flanges Manufacturers in India

- Inconel 601 BS 4504 Flanges

- Inconel Alloy 601 Orifice Flanges

Inconel 601 Flanges are specialized flanges made from Inconel 601, a nickel-chromium alloy known for its excellent oxidation resistance and mechanical strength. They are commonly used in high-temperature applications and environments where corrosion resistance is crucial.

Inconel 601 Flanges are used in various applications, including thermal processing equipment, pollution control, aerospace components, and power generation systems. They are ideal for use in radiant tubes, strand annealing tubes, steam super-heater tube supports, and jet-engine igniters.

The benefits of using Inconel 601 Flanges include exceptional corrosion resistance, high mechanical strength, resistance to thermal cycling, and the ability to withstand high temperatures. They provide reliable performance in harsh environments.

Inconel 601 Flanges are manufactured using conventional techniques to ensure high quality and precision. Processes may include forging, machining, and welding, tailored to meet specific standards and requirements.

Inconel 601 Flanges comply with various industry standards, including ASTM, ASME, and ANSI specifications, ensuring they meet rigorous performance and safety requirements.

Inconel 601 Pipe Flanges Test Certificates

At Dhanratan Steel Industries, we provide comprehensive Manufacturer Test Certificates (TC) by EN 10204/3.1B. Our offerings include raw materials certificates, 100% radiography test reports, and Third Party reports. Additionally, we can provide standard certificates such as EN 10204 3.1, along with extra requirements like NACE MR 01075 and ferrite content certification as requested by our clients.

Our standard documentation includes:

- EN 10204/3.1B

- Raw Materials Certificate

- 100% Radiography Test Report

- Third Party Inspection Report, etc.

ASTM, ASME Inconel 601 Flanges Value Added Services

Material Testing: At Dhanratan Steel Industries, we ensure that all our materials undergo rigorous quality tests before they are dispatched to our clients. Our testing services include:

- Mechanical Testing, such as Tensile Strength and Yield Strength

- Hardness Testing

- Chemical Analysis—Spectro Analysis

- Positive Material Identification—PMI Testing

- Flattening Tests

- Micro and Macro Examination

- Pitting Resistance Testing

- Flaring Tests

- Intergranular Corrosion (IGC) Testing

Documentation:

We provide extensive documentation to ensure transparency and traceability, including:

- Commercial Invoice, which includes HS Code

- Packing List detailing net weight, gross weight, number of boxes, Marks, and Numbers

- Certificate of Origin legalised or attested by the Chamber of Commerce or Embassy

- Fumigation Certificates

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan (QAP)

- Heat Treatment Charts

- Test Certificates certifying compliance with NACE MR0103 and NACE MR0175

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

- Guarantee Letter

- NABL Approved Laboratory Test Reports

- Welding Procedure Specification/Procedure Qualification Record (WPS/PQR)

- Form A for the Generalized System of Preferences (GSP)

Inconel 601 Pipe Flanges Packaging

Inconel 601 flanges are extensively used across various industries, including petrochemicals, oil and gas, power generation, bulk liquid transportation, chemicals, pharmaceuticals, pulp and paper manufacturing, textiles, and more. All our Inconel 601 Flanges are manufactured in accordance with international standards.

We implement thorough packaging procedures to ensure the safety of our flanges during transit. For exports, we use standard export packaging in wooden cases. Each Inconel 601 Pipe Flange is marked with essential information, including grade, lot, size, degree, and our trademark. We also offer custom marking on Inconel 601 Flanges upon special request.