Inconel 625 is a nickel-based alloy known for its exceptional strength, corrosion resistance, and high-temperature performance. This material is widely used in industrial applications such as gas turbines, chemical processing, and aerospace engineering. One of the most popular uses of Inconel 625 is in flanges, critical components of a pipeline system that connect pipes, valves, and other equipment.

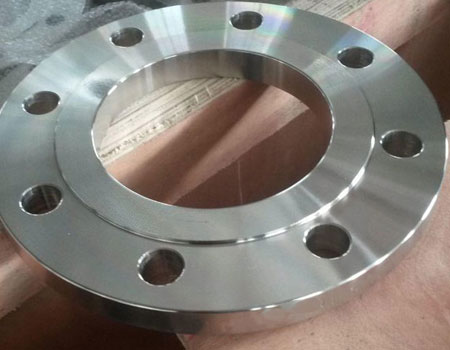

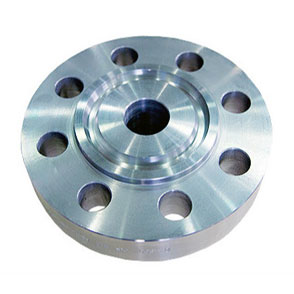

Inconel 625 flanges come in several types, including weld neck flanges, slip-on flanges, threaded flanges, and socket weld flanges. Weld neck flanges are the most common type of Inconel 625 flanges and are generally used in high-pressure and high-temperature applications. Slip-on and threaded flanges are used in low-pressure systems, while socket weld flanges are ideal for small pipe diameters.

Inconel 625 RTJ Flange, INCONEL 625 FORGED FLANGES, Inconel 625 Spectacle Blind Flanges, Inconel 625 Slip On Flanges, Inconel 625 Screwed Flanges Stockist, 625 Inconel Nipoflange Manufacturers in India.

Inconel 625 flanges are widely used in several industries because of their excellent corrosion resistance. These flanges are particularly suitable for applications in harsh environments such as chemical processing, offshore oil and gas, and marine engineering. Inconel 625 flanges are also used in power generation, where high-temperature applications demand materials that can withstand extreme heat and pressure.

Inconel 625 WNRF Flange, Inconel 625 DIN Flanges, Inconel 625 RTJ Flanges, Inconel 625 Nippolet Flanges, Inconel 625 Plate flange, Inconel 625 Forged Flanges Manufacturers in India.

Inconel 625 flanges have many uses in a pipeline system. They are crucial in connecting pipes, valves, and other equipment. Flanges make assembling and disassembling a pipeline system easy, which is crucial during maintenance and repair work. Inconel 625 flanges also provide a leak-proof connection, essential for hazardous materials or corrosive substances. Moreover, Inconel 625 is a highly malleable material that can be formed into complex shapes, making it ideal for customized flanges.

Inconel 625 flanges offer several benefits that make them popular for pipeline systems. One of the main advantages of Inconel 625 is its excellent corrosion resistance. This material can withstand harsh chemicals, acids, and saltwater, which is essential for pipelines in offshore oil, gas, and marine environments. Inconel 625 also has high strength and is resistant to fatigue, making it ideal for high-pressure and high-temperature systems. Moreover, Inconel 625 is a versatile material easily fabricated into different components, including flanges, without compromising its mechanical properties.

Inconel 625 flanges are a critical component of a pipeline system that provides a leak-proof connection and ensures the smooth flow of substances. These flanges are ideal for applications in harsh environments and industries demanding high temperatures and pressure. Inconel 625 flanges are available in different types, sizes, and pressure classes to fit specific pipeline requirements.

Inconel 625 Flanges Specification

| Standard | ASTM B564 / ASME SB564 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flange Size Chart | 1/2" (15 NB) to 48" (1200NB), DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Flange Connection / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove, Flange Pipe. |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Types of Flanges | Threaded / Screwed / Forged / Plate |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Test Of Flange | Direct-reading Spectrograph, Ultrasonic flaw detector, Magnetic particle detector, X-ray detector, Hydrostatic testing machine. |

| Production technique Used | Heat treated, Forged and Machined |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc. |

| Test Certificates | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc |

Inconel 625 Flange Price List

| Price List of Inconel 625 Flanges | Inconel Alloy 625 Flange Price in India (INR) | Inconel 625 Flanges Price in USD | Inconel Alloy 625 Flanges Price in UAE (Dirham) |

|---|---|---|---|

| Inconel 625 Threaded Flanges Price | ₹ 1528 | $ 17.62 USD | 50.60 AED |

| Price of Inconel 625 Flanges | ₹ 1650 | $ 23.78 USD | 74.50 AED |

| Inconel Alloy 625 Flanges Price List | ₹ 1254 | $ 27.60 USD | 74.50 AED |

| Alloy 625 Flange Price | ₹ 1264 | $ 10.59 USD | 62.52 AED |

| Inconel Alloy 625 Raised Face Blind Flange | ₹ 1157 | $ 11.53 USD | 37.17 AED |

| Inconel Alloy 625 Flanges Price | ₹ 1250 | $ 16.24 USD | 24.50 AED |

| Inconel Alloy 625 Flange Price Per Kg | ₹ 870 | $ 16.69 USD | 54.02 AED |

| Inconel Alloy 625 Flange Price List India | ₹ 1684 | $ 27.50 USD | 162.00 AED |

Inconel 625 Flanges Technical Data Sheet

Inconel 625 Pipe Flanges Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

Inconel Alloy 625 Flanges Manufacturing Process

Common Types Of Inconel 625 Flanges

Inconel Alloy 625 Weld Neck Flanges

Alloy 625 Blind Flanges

UNS N06625 Socket Weld Flanges

Inconel Alloy 625 Slip-on Flanges

Inconel 625 RTJ Flange

Inconel Alloy 625 Forged Flanges

Alloy 625 Lap Joint Flanges

Inconel Alloy 625 Threaded Flanges

Inconel Alloy 625 Spectacle Blind Flange

Other Type Inconel Alloy 625 Flanges

- Alloy 625 Reducing Flanges

- Inconel 625 Square Flanges

- Inconel Alloy 625 Flange Dimensions

- Inconel 625 Flanges Suppliers in India

- Inconel Alloy 625 Threaded Flanges

- ASTM B564 Inconel Alloy 625 Plate Flange

- Inconel 625 Socket Weld Flanges

- Alloy 625 Flanges Manufacturer in Mumbai

- Inconel Alloy 625 Socket weld Flanges

- Inconel 625 Flat Face Flange

- Inconel 625 Weld Neck Flanges

- Alloy 625 Square Flanges

- Alloy 625 Flat Flange

- Alloy 625 Forged Flanges

- UNS N06625 Flanges

- Inconel 2.4856 Raised Face Flanges

- UNS N06625 Long Weld Neck Flanges

- Inconel 625 Lap Joint Flanges

- Inconel Alloy 625 Flanges Manufacturers in India

- Inconel 2.4856 Plate Flanges

- ANSI B16.5 Alloy 625 Pipe Flanges

- Inconel 625 Flanges Suppliers in Mumbai

- Inconel 625 Flanges Manufacturers in India

- Alloy 625 Slip on Flanges

- Inconel Alloy 625 Pipe Flanges

- Inconel Alloy 625 Orifice Flanges

- Inconel® Alloy 625 Reducing Flanges

- B564 UNS N06625 Blind Flanges

- Inconel 625 BS 4504 Flanges

- Alloy 625 Ring Type Joint Flanges

- ASME SB564 Inconel Alloy 625 Pipe Flange

- UNS N06625 Plate Flanges

- Inconel Alloy 625 Flanges Suppliers in Mumbai

- Inconel Alloy 625 Flange Suppliers in India

- Inconel Alloy 625 Industrial Flanges

- 2.4856 Pipe Flanges

- Alloy 625 Orifice Flanges

- Inconel Alloy 625 Lapped Joint Flanges

Inconel Alloy 625 Flanges Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | - | 5.0 max | 58.0 min | 20.0 - 23.0 |

Inconel Alloy 625 Flange Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |