Inconel 625 is a super alloy that has gained popularity over the years due to its excellent resistance to corrosion, high strength, and temperature stability. Inconel 625 fasteners are widely used in different applications across several industries. These fasteners are incredibly versatile, making them a go-to choice for engineers and industry players.

Inconel 625 Screws, 625 Inconel Fasteners, DIN933 Hardware Fasteners, Alloy 625 Fasteners, Inconel Alloy 625 Nuts, Inconel® Alloy 625 Fasteners, Nickel Alloy 625 Fasteners, Inconel 625 Fasteners Manufacturers in India.

Inconel 625 Fasteners come in different types, such as bolts, nuts, screws, washers, and studs. These fasteners are classified into two main categories - imperial and metric sizes. The imperial types have threads on the stud portion of the fastener, while the metric sizes are categorized by size and pitch. Inconel 625 fasteners are available in various shapes, sizes, and finishes to cater to different applications across different fields.

625 Inconel Screw, Inconel Alloy 625 Washers, Inconel Alloy 625 Fasteners, Nickel Alloy 625 Fasteners, Alloy 625 Bolts, ASTM F468 N06625 Fasteners, Inconel® Alloy 625 Fasteners Manufacturer, UNS N06625 Grade 2 Fasteners, Inconel 625 Fasteners Manufacturers In Mumbai.

The aerospace industry has embraced Inconel 625 fasteners due to their high strength, corrosion resistance, and temperature stability, making them a perfect fit in harsh environments. Inconel 625 fasteners are used in various aerospace applications such as engines, gas turbines, heat exchangers, and exhaust systems. Inconel 625 fasteners are also widely used in the chemical processing industry due to their resistance to acidic and corrosive environments. They are used in piping systems, heat exchangers, and reactors.

The versatility of Inconel 625 fasteners makes them useful in several applications. They are commonly used in high-temperature environments where stability and durability are essential. Inconel 625 fasteners are also widely used in environments with high stress, vibration, and corrosion levels. These fasteners are well-suited for applications in which strength and reliability are vital. They are commonly used in turbine engines, chemical processing, and the oil and gas industry.

Inconel 625 fasteners have several benefits that make them ideal for different applications. They have high-strength and corrosion resistance, making them reliable in harsh environments. They are versatile and come in various sizes, shapes, and finishes, making them usable in different applications. They are resistant to seawater, making them ideal for use in the marine industry. They have high-temperature stability, making them useful in high-temperature environments.

Inconel 625 fasteners have become popular in different industries due to their high strength, temperature stability, and corrosion resistance. With various sizes, shapes, and finishes, these fasteners are versatile and useful in different applications. Inconel 625 fasteners offer benefits such as corrosion resistance, high-temperature stability, and versatility, making them a preferred choice for industry players.

Inconel 625 Fasteners Specification

| Standard | ASTM F468 / ASME SF468 |

| Bolt / Screw Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Nuts Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Washers Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Machine Screws Size | M1.6 – M12 |

| Self Tapping Screw Size | No.2 – No. 14 |

| Length | 3 mm to 200 mm |

| Threads | UNF, BSW, BSF, METRIC, UNC, or as required |

| Fasteners |

|

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Raw materials Source | JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin,etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

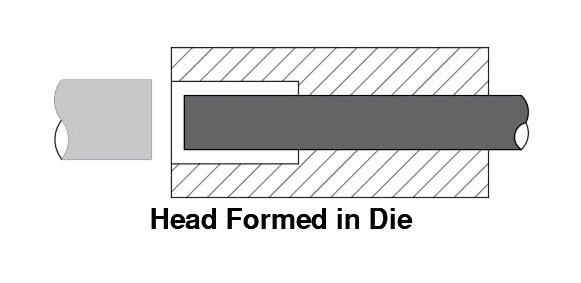

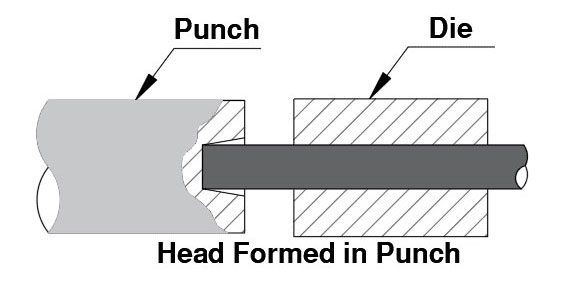

| Production Process | M24-M100: hot forging , M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Types | Bolts, Nuts, Stud Bolts, Washers, Threaded Rod, Anchor Fasteners, Eye Bolt, Stud, Cotter Pin, Socket Screw, Fine Fasteners & Spares, Foundation Fasteners, Hexagon Castle Nuts, Hexagon Domed Cap Bolts, Hexagon Thin Nuts etc. |

Inconel 625 Fasteners Price List

| Price List of Inconel 625 Fasteners | Inconel Alloy 625 Fasteners Price in India (INR) | Alloy 625 Fasteners Price in USD | Nickel Alloy 625 Fasteners Price in UAE (Dirham) |

|---|---|---|---|

| Nickel Alloy 625 Fasteners Price List | ₹ 3,536 | $ 44.33 USD | 155.17 AED |

| M8 Inconel 625 Hex Flange Nut Price | ₹ 2,249 | $ 25.19 USD | 48.76 AED |

| 625 Inconel Nut Bolt Price List | ₹ 1,375 | $ 29.35 USD | 79.73 AED |

| Alloy 625 Nut Bolt Price Per Kg | ₹ 2,337 | $ 36.00 USD | 65.10 AED |

| Price of Inconel 625 Stud Bolt | ₹ 5,343 | $ 66.70 USD | 156.71 AED |

| Inconel 625 Hex Bolt Price List | ₹ 4,442 | $ 247.32 USD | 468.50 AED |

| Inconel® Alloy 625 Bolts Price List | ₹ 2,678 | $ 68.45 USD | 55.27 AED |

| Inconel 625 Screws Price | ₹ 2,228 | $ 23.72 USD | 96.45 AED |

| M16 5/8inch Inconel 625 Hex Head Bolt Price List | ₹ 1,334 | $ 36.21 USD | 154.27 AED |

Inconel 625 Fasteners Technical Data Sheet

Inconel 625 Fasteners Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

Inconel 625 Fasteners Manufacturing Process

Common Types Of Inconel 625 Fasteners

Inconel® Alloy 625 Bolts

625 Inconel Nuts

Inconel Alloy 625 Steel Screw

Alloy 625 Washer

Nickel Alloy 625 Stud Bolts

Inconel 625 Anchor Bolts

Other Type Inconel 625 Fasteners

- 625 Inconel Heavy Hex Nuts

- Inconel® Alloy 625 Anchor Fasteners

- Inconel 625 Fasteners Manufacturers in Mumbai

- 625 Inconel Structural Bolts

- UNS N06625 Washers

- ASTM F468 Inconel 625 Fasteners

- 625 Inconel Industrial Fasteners Distributors

- Inconel Alloy 625 Fasteners Supplier

- M10 Inconel 625 Bolts

- Inconel 625 Fasteners Manufacturers in India

- M12 Inconel 625 Nuts

- Nickel Alloy 625 Fasteners Manufacturers in Mumbai

- Inconel 625 Fasteners Suppliers in India

- Alloy 625 Anchor Fasteners

- Inconel Alloy 625 Fasteners Stock

- M6 Inconel 625 Washers

- Nickel Alloy 625 Coupling Nuts

- Inconel Alloy 625 Fasteners Suppliers in Mumbai

- 625 Inconel Stud Bolts

- Inconel® Alloy 625 Lug Nuts

- Inconel Alloy 625 Fasteners Manufacturers in India

- Inconel 625 Hex Nuts

- UNS N06625 Eye Bolts

- Inconel 625 Heavy Hex Bolts

- Alloy 625 Fasteners Suppliers in India

- Alloy 625 Fasteners Exporters

- Inconel 2.4856 Hex Bolt

- Nickel Alloy 625 U Bolts

- Self Tapping Inconel 625 Screws

- Inconel 625 Fasteners Suppliers in Mumbai

Inconel 625 Fasteners Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Inconel 625 Fasteners Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 625 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |