Inconel 601 pipes and tubes are often the preferred choice for high-temperature applications. This alloy is known for its excellent resistance to heat, corrosion, and oxidation. Inconel 601 is a nickel-chromium alloy that is strengthened with aluminium. It is often used in the chemical processing industry due to its high-temperature strength and resistance to corrosion.

Inconel 601 is available in various forms, including pipes, tubes, bars, sheets, and plates. However, pipes and tubes are widely used in various high-temperature applications. Inconel 601 pipes and tubes come in several sizes and thicknesses to suit different applications. Inconel 601 seamless pipes are highly preferred because of their superior corrosion resistance and high-temperature strength. Welded Inconel 601 pipes and tubes are also popular and often used in applications with lower stress levels.

Inconel 601 Pipe, ASTM B516 Inconel Alloy 601 ERW Tubes, Inconel 601 Tubing, Inconel Alloy 601 Tube, Inconel Alloy 601 Square Pipes, ASTM B167 Inconel® Alloy Rectangular Pipes, Inconel 601 Tube Manufacturers India.

Inconel 601 is suitable for high-temperature applications, including furnace muffles, heat exchangers, petrochemical processing, and aerospace applications. It is also used in sintering trays, industrial furnace parts, and chemical processing applications. Inconel 601 pipes and tubes are also extensively used in power generation equipment, such as gas turbine blades, combustion cans, and heat shields.

Inconel 601 Seamless Pipe, Inconel 601 ERW Pipe, Inconel® Alloy 601 Pipes and Tubes, Inconel Alloy 601 Pipe, Inconel Alloy 601 Tubing, Nickel Alloy 601 Welded Tubing Exporter, Inconel 601 Pipe Manufacturers in India.

Inconel 601 pipes and tubes are often used in aggressive environments, such as those in the chemical processing industry. This material is resistant to hydrocarbon and sulfate combustion gases, making it ideal for use as a gas turbine exhaust stack lining. The alloy's high-temperature strength and resistance to thermal fatigue make it suitable for use in aircraft exhaust systems. Inconel 601 pipes and tubes are also used in manufacturing equipment and semiconductor components.

The benefits of using Inconel 601 pipes and tubes are numerous. It offers superior resistance to high-temperature oxidation and carburization. It is also highly corrosion-resistant, making it ideal for harsh environments. The metal's excellent mechanical properties also improve its durability, making it a smart choice for long-term investment. Inconel 601's high-temperature strength enables it to withstand high thermal stresses, reducing the risk of system failure.

Inconel 601 pipes and tubes are the go-to choice for high-temperature applications with critical durability, strength, and corrosion resistance. Its versatility and chemical stability make it an excellent material for various industrial applications, from aerospace to semiconductor manufacturing, chemical processing, and more.

Inconel 601 Pipes And Tubes Specifications

| Pipe Specifications | ASTM B167, B516 / ASME SB167, SB516 |

| Tube Specifications | ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554 |

| Dimensions | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless Pipe & Tube Size | 1/2″ NB – 16″ NB |

| Welded Pipe & Tube Size | 1/8″NB TO 30″NB IN |

| EFW Pipe & Tube Size | 6″ NB – 24″ NB |

| Tube Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness | 0.35 mm – 50 mm |

| Specialized in | Large Diameter Pipe Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless Pipes, ERW Pipes, Welded Pipe, Fabricated Pipes, Electropolished Pipe, Polished Pipe, Hollow Pipes |

| Form | Round, Square, Hydraulic, U Shape, Rectangular, Pan Cake Coils, Coiled, Hex, Honed, Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded End |

Inconel 601 Pipes And Tubes Price List

| Price List of Inconel 601 Pipes and Tubes | Inconel 601 Pipes and Tubes Price in India (INR) | Inconel Alloy 601 Pipes and Tubes Price in USD | Inconel 601 Pipes and Tubes Price in UAE (Dirham) |

|---|---|---|---|

| 2 inch Inconel Alloy 601 Pipe Price | ₹ 506 | $ 67.27 USD | 20.60 AED |

| Inconel 601 Tube Price | ₹ 167 | $ 6.09 USD | 9.60 AED |

| Inconel Alloy 601 Pipes Price List | ₹ 963 | $ 16.97 USD | 47.10 AED |

| Inconel Steel Pipe 601 Price Per Kg | ₹ 185 | $ 2.32 USD | 5.58 AED |

| Inconel 601 Pipe Price Per Kg | ₹ 480 | $ 5.26 USD | 25.44 AED |

| Inconel Alloy 601 Pipe Price | ₹ 174 | $ 3.50 USD | 8.77 AED |

| Price of Inconel 601 Seamless Pipes | ₹ 485 | $ 6.60 USD | 20.00 AED |

| Nickel Alloy 601 Price | ₹ 163 | $ 3.50 USD | 8.54 AED |

Inconel 601 Pipes And Tubes Technical Data Sheet

Inconel 601 Pipes And Tubes Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| Inconel Alloy 601 | N06601 | 2.4851 | NCF 601 | NC23FeA | NA 49 | XH60BT | NiCr23Fe |

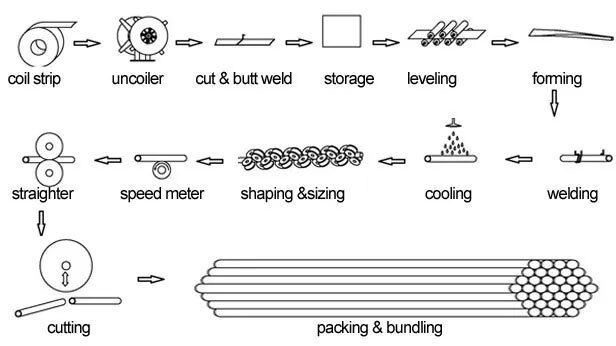

Inconel 601 Pipes And Tubes Manufacturing Process

Common Types Of Inconel 601 Pipes And Tubes

Inconel 601 Seamless Pipe

Inconel 601 Welded Pipe

Inconel 601 ERW Pipe

Inconel 601 EFW Pipe

Inconel 601 Seamless Tube

Inconel Alloy 601 Welded Tube

Inconel Alloy 601 Capillary Tube

Inconel Alloy 601 Heat Exchanger Tubes

Inconel Alloy 601 Square Tubes

Other Type Inconel 601 Pipes And Tubes

- Inconel Alloy 601 High pressure Pipes

- Inconel 601 Round Tubing

- UNS N06601 Pipes

- Inconel 2.4851 Seamless Tubing

- Inconel 601 Welded Pipe

- Nickel Alloy 601 Thin Wall Tube

- Inconel 601 Pipes Manufacturer in Mumbai

- ASTM B167 Inconel® Alloy Round Pipe

- Schedule 40 Inconel Alloy 601 Pipe

- Inconel Alloy 601 Rectangular Tube

- Inconel 601 Oval Tubing

- Inconel 601 Pipe Suppliers in India

- Nickel Alloy 601 Tubes

- Inconel Alloy 601 Pipe

- Large Diameter Inconel 601 Pipe

- Inconel 601 Square Pipe

- Inconel 601 Electropolished Pipe

- Inconel Alloy 601 Coil Tubing

- Inconel 601 Pipe Manufacturers in India

- ASME SA213 Inconel Alloy 601 Tubes

- UNS N06601 Tubing

- Inconel Alloy 601 Rectangular pipe

- Inconel 601 Welded Pipe

- Inconel 601 Tubes Suppliers in Mumbai

- Nickel Alloy 601 Thick Wall Tube

- Inconel Alloy 601 Hollow Pipe

- Nickel Alloy 601 Tube

- 2.4851 Seamless Pipe

- Inconel 2.4851 Thick Wall Pipe

- ASTM A213 Inconel Alloy 601 Welded Tube

- Inconel Alloy 601 Polished Pipe

- Inconel 601 Tubes Suppliers in India

- Inconel Alloy 601 Industrial Pipes

- Inconel 601 Pipe Suppliers in Mumbai

- ASME SB167 Inconel Alloy 601 Pipes

- Inconel 601 Pipe Manufacturers in India

- Inconel Alloy 601 Boiler Tubes

- Inconel Alloy 601 Hydraulic Tubing

Inconel 601 Pipes And Tubes Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Inconel 601 Pipes And Tubes Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |