Incoloy 825 pipes and tubes are a type of high-performance alloy that is highly resistant to corrosion and can withstand extreme temperatures. These pipes and tubes have become increasingly popular across different industries due to their superior quality, strength, and durability.

Incoloy 825 pipes and tubes are available in several types with varying strength, resistance, and durability levels. Some of the most popular types include standard seamless pipes, welded pipes, seamless tubes, and welded tubes. Standard seamless pipes are commonly used in high-pressure applications with critical strength and durability. On the other hand, welded pipes are ideal for industrial applications, which can be used in various corrosive environments. Seamless and welded tubes are commonly used as heat exchangers in chemical processing plants, power generation plants, and other industrial applications.

Incoloy Alloy 825 Square Pipes, Incoloy 825 Tubing, Incoloy Alloy 825 Tube, ASTM B407 Incoloy® Alloy Rectangular Pipes, Alloy 825 Pipe, ASTM B514 Incoloy Alloy 825 ERW Tubes, Alloy 825 Tube Manufacturers India.

Incoloy 825 pipes and tubes have various applications across different industries. They are commonly used in the petrochemical, chemical, marine, and oil and gas industries, where they are used in various applications such as heat exchangers, pressure vessels, piping systems, and more. In addition, these pipes and tubes are also used in desalination plants, where they help to desalinate seawater, making it safe for human consumption. They are also used in air pollution control equipment and acid production plants.

Incoloy Alloy 825 Tubing, Incoloy® Alloy 825 Pipes and Tubes, Incoloy Alloy 825 Pipe, Nickel Alloy 825 Welded Tubing Exporter, Incoloy 825 Seamless Pipe, Incoloy 825 ERW Pipe, Incoloy 825 Pipe Manufacturers in India.

The superior quality, strength, and durability of Incoloy 825 pipes and tubes make them ideal for various uses. These pipes and tubes resist corrosion, oxidation, and pitting, making them ideal for corrosive environments. They can withstand high temperatures and pressures and are perfect for high-stress applications. In addition, these pipes and tubes are easy to maintain and have a long lifespan, making them a cost-effective option for many industries.

There are several benefits of using Incoloy 825 pipes and tubes. They offer superior resistance to corrosion and can withstand the corrosive effects of several chemicals, making them ideal for use in corrosive environments. They offer excellent strength and durability and can withstand high temperatures and pressures. That makes them ideal for use in various high-stress applications. These pipes and tubes are easy to install and maintain, which makes them a cost-effective option for many industries.

Incoloy 825 pipes and tubes are an ideal option for various industries due to their superior quality, strength, and durability. They offer a range of benefits, from resistance to corrosion and high temperatures to cost-effectiveness and ease of maintenance.

Incoloy Alloy 825 Pipe Specifications

| Pipe Specifications | ASTM B407, B514 / ASME SB407, SB514 |

| Tube Specifications | ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554 |

| Dimensions | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless Pipe & Tube Size | 1/2″ NB – 16″ NB |

| Welded Pipe & Tube Size | 1/8″NB TO 30″NB IN |

| EFW Pipe & Tube Size | 6″ NB – 24″ NB |

| Tube Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness | 0.35 mm – 50 mm |

| Specialized in | Large Diameter Pipe Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless Pipes, ERW Pipes, Welded Pipe, Fabricated Pipes, Electropolished Pipe, Polished Pipe, Hollow Pipes |

| Form | Round, Square, Hydraulic, U Shape, Rectangular, Pan Cake Coils, Coiled, Hex, Honed, Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded End |

Incoloy 825 Pipes and Tubes Price List

| Price List of Incoloy 825 Pipes and Tubes | Incoloy 825 Pipes and Tubes Price in India (INR) | Incoloy Alloy 825 Pipes and Tubes Price in USD | Incoloy 825 Pipes and Tubes Price in UAE (Dirham) |

|---|---|---|---|

| Incoloy Alloy 825 Pipes Price List | ₹ 1230 | $ 17.97 USD | 45.10 AED |

| Incoloy Steel Pipe 718 Price Per Kg | ₹ 185 | $ 2.30 USD | 5.58 AED |

| Incoloy 825 Tube Price | ₹ 247 | $ 6.09 USD | 9.60 AED |

| Incoloy Alloy 825 Pipe Price | ₹ 254 | $ 3.60 USD | 8.00 AED |

| Price of Incoloy 825 Seamless Pipes | ₹ 585 | $ 5.47 USD | 23.50 AED |

| Nickel Alloy 825 Price | ₹ 273 | $ 3.50 USD | 8.50 AED |

| 2 inch Incoloy Alloy 825 Pipe Price | ₹ 576 | $ 62.23 USD | 23.60 AED |

| Incoloy 825 Pipe Price Per Kg | ₹ 480 | $ 4.23 USD | 26.40 AED |

Incoloy 825 Pipes and Tubes Technical Data Sheet

Incoloy 825 Pipes and Tubes Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Incoloy 825 | 2.4858 | N08825 |

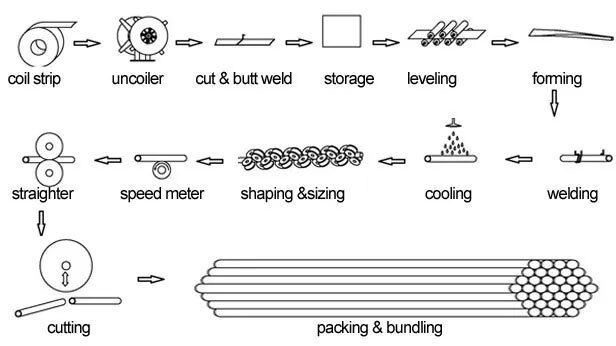

Incoloy Alloy 825 Pipes and Tubes Manufacturing Process

Common Types Of Incoloy 825 Pipes and Tubes

Incoloy 825 Seamless Pipe

Incoloy 825 Welded Pipe

Incoloy 825 ERW Pipe

Incoloy 825 EFW Pipe

Incoloy 825 Seamless Tube

Incoloy Alloy 825 Welded Tube

Incoloy Alloy 825 Capillary Tube

Incoloy Alloy 825 Heat Exchanger Tubes

Incoloy Alloy 825 Square Tubes

Other Type Incoloy Alloy 825 Pipes and Tubes

- Incoloy Alloy 825 Pipe

- Large Diameter Incoloy 825 Pipe

- Incoloy 825 Pipes Manufacturer in Mumbai

- Incoloy Alloy 825 Rectangular Tube

- Incoloy Alloy 825 High pressure Pipes

- Incoloy 825 Oval Tubing

- Schedule 40 Incoloy Alloy 825 Pipe

- Incoloy Alloy 825 Coil Tubing

- Nickel Alloy 825 Tubes

- Incoloy 2.4858 Seamless Tubing

- ASTM B407 Inconel® Alloy Round Pipe

- Nickel Alloy 825 Thin Wall Tube

- Incoloy 825 Electropolished Pipe

- Incoloy 825 Round Tubing

- Incoloy 825 Square Pipe

- Incoloy 825 Welded Pipe

- Incoloy 825 Pipe Suppliers in India

- UNS N08825 Pipes

- Incoloy 825 Pipe Manufacturers in India

- Incoloy 825 Pipe Suppliers in Mumbai

- Incoloy 825 Pipe Manufacturers in India

- ASME SB407 Incoloy Alloy 825 Pipes

- Incoloy Alloy 825 Polished Pipe

- Incoloy Alloy 825 Hollow Pipe

- Incoloy Alloy 825 Hydraulic Tubing

- Nickel Alloy 825 Thick Wall Tube

- Incoloy 825 Welded Pipe

- 2.4858 Seamless Pipe

- Incoloy Alloy 825 Industrial Pipes

- UNS N08825 Tubing

- Incoloy 825 Tubes Suppliers in India

- Nickel Alloy 825 Tube

- Incoloy Alloy 825 Boiler Tubes

- Inconel 2.4858 Thick Wall Pipe

- Incoloy 825 Tubes Suppliers in Mumbai

- ASME SA213 Incoloy Alloy 825 Tubes

- Incoloy Alloy 825 Rectangular pipe

- ASTM A213 Incoloy Alloy 825 Welded Tube

Incoloy® Alloy Tubing Chemical Composition

| Grade | C | Mn | Si | Cu | S | Fe | Mo | Ni | Cr |

|---|---|---|---|---|---|---|---|---|---|

| Incoloy 825 | 0.08 max | 0.35 max | 0.35 max | 0.3 max | 0.015 max | Bal | 2.8 – 3.3 | 50 – 55 | Bal |

Incoloy 825 Pipes Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.1 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 70,000 , MPa – 482 | 45 % |