Stainless steel is a popular material for pipes and tubes because of its durability, resistance to corrosion, and ability to withstand high temperatures. One type of stainless steel commonly used in various industries is 317 / 317L. These materials are known for their excellent corrosion resistance and high strength.

Stainless steel 317 and 317L contains chromium, nickel, and molybdenum, making them highly resistant to oxidation and corrosion. Different types of stainless steel 317 pipes and tubes include seamless, welded, and erw pipes. Seamless pipes are made from a solid billet that is heated and pulled over a mandrel to form a tube without welding. Welded pipes, conversely, are formed by rolling a strip of steel into a tube and welding the edges together. ERW pipes are made by cold-forming a steel plate into a cylindrical shape and then welding the edges.

317L Stainless Steel Pipe, Stainless Steel 317 Tubing, 317L Stainless Steel Tube, Jindal 317 Stainless Steel Pipe, Stainless Steel 317L Pipe, 317 Stainless Steel Pipe, SS 317 Pipe, SS 317 Pipe HSN Code, SS 317 Tube Manufacturers India.

Stainless steel 317L pipes and tubes are widely used in various industries, such as chemical processing, petrochemicals, paper and pulp, aerospace, food processing, and architecture. They are used in equipment that comes in contact with highly corrosive materials, such as acids, alkalis, and chlorides. These pipes and tubes are also used in high-temperature applications, such as steam generators, heat exchangers, and superheats.

UNS S31703 Pipes, 317L Stainless Steel Tubing, Stainless Steel 317 Seamless Pipe, 317 SS Pipes and Tubes, 16 Gauge 317 Stainless Steel Pipe, 317 Stainless Steel Square Tubing, SS 317 Pipe Manufacturers in India.

Stainless steel 317 / 317L pipes and tubes are used in many applications, including low lines, heat exchangers, boilers, condensers, process piping, and architectural applications. These materials are corrosion-resistant, even in harsh environments, and can withstand high temperatures. They are also easy to fabricate and maintain, making them a popular choice for various industries.

Stainless steel 317 / 317L pipes and tubes provide many benefits, including resistance to corrosion, toughness, strength, and ease of fabrication. These materials can withstand high temperatures and are highly resistant to oxidation and corrosion, even in harsh environments. They are also easy to maintain and can be welded, formed, and machined into various shapes and sizes. Moreover, stainless steel 317 / 317L pipes and tubes are cost-effective, especially in the long run, because they require minimal maintenance and have a long lifespan.

Stainless steel 317 / 317L pipes and tubes are widely used in various industries because of their strength, resistance to corrosion, and ability to withstand high temperatures. These materials come in different types, including seamless, welded, and erw pipes, and can be used in various applications, such as flowlines, heat exchangers, and boilers. Stainless steel 317 / 317L pipes and tubes give many benefits, including durability, toughness, and ease of fabrication. They are also cost-effective in the long run, making them an ideal material for different industries.

317 Stainless Steel Pipe Specifications

| Pipe Specifications | ASTM A312, A358 / ASME SA312, SA358 |

| Tube Specifications | ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554 |

| Dimensions | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless Pipe & Tube Size | 1/2″ NB – 16″ NB |

| Welded Pipe & Tube Size | 1/8″NB TO 30″NB IN |

| EFW Pipe & Tube Size | 6″ NB – 24″ NB |

| Tube Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness | 0.35 mm – 50 mm |

| Specialized in | Large Diameter Pipe Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless Pipes, ERW Pipes, Welded Pipe, Fabricated Pipes, Electropolished Pipe, Polished Pipe, Hollow Pipes |

| Form | Round, Square, Hydraulic, U Shape, Rectangular, Pan Cake Coils, Coiled, Hex, Honed, Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded End |

SS 317 Pipes and Tubes Price List

| Price List of Stainless Steel 317 Pipes and Tubes | SS 317 Pipes and Tubes Price in India (INR) | SS 317L Pipes and Tubes Price in USD | SS 317L Pipes and Tubes Price in UAE (Dirham) |

|---|---|---|---|

| Price of Stainless Steel 317L Seamless Pipes | ₹ 450 | $ 5.49 USD | 21.51 AED |

| SS 317L Pipe Price | ₹ 166 | $ 2.21 USD | 8.13 AED |

| 2 inch 317 Stainless Steel Pipe Price | ₹ 576 | $ 6.67 USD | 24.24 AED |

| Jindal Steel Pipe 317 Price Per Kg | ₹ 165 | $ 1.32 USD | 5.47 AED |

| Jindal SS 317 Pipes Price List | ₹ 923 | $ 11.97 USD | 41.27 AED |

| SS 317 Pipe Price Per Kg | ₹ 349 | $ 3.36 USD | 15.01 AED |

| 317 Stainless Steel Tube Price | ₹ 147 | $ 2.39 USD | 9.26 AED |

| SS Pipe 317 Price | ₹ 143 | $ 2.21 USD | 8.58 AED |

Stainless Steel 317 Pipes and Tubes Technical Data Sheet

Stainless Steel 317 Pipes and Tubes Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

|---|---|---|---|---|

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

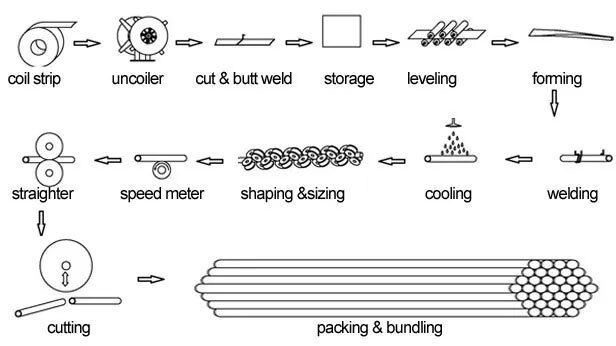

317L Stainless Steel Pipes and Tubes Manufacturing Process

Common Types Of Stainless Steel 317 Pipes and Tubes

SS 317 Seamless Pipe

SS 317 Welded Pipe

SS 317 ERW Pipe

SS 317L EFW Pipe

Stainless Steel 317L Seamless Tube

317L Stainless Steel Welded Tube

317 Stainless Steel Capillary Tube

317L Stainless Steel Heat Exchanger Tubes

317 Stainless Steel Square Tubes

Other Type 317 Stainless Steel Pipes and Tubes

- SS 317L Thin Wall Tube

- 317 Stainless Steel Coil Tubing

- Stainless Steel 317 Pipe Suppliers in India

- Stainless Steel 317L Welded Pipe

- SS 317L Square Pipe

- 317 Stainless Steel Rectangular Tube

- Large Diameter Stainless Steel 317L Pipe

- Stainless Steel 1.4438 Seamless Tubing

- SS 317 Pipe Manufacturers in India

- 317 Stainless Steel Pipe

- SS 317 Electropolished Pipe

- Schedule 40 317 Stainless Steel Pipe

- SS 317L Oval Tubing

- Stainless Steel 317 Tubes

- Stainless Steel 317 Round Tubing

- UNS S31700 Pipes

- ASTM A312 TP317L SS Round Pipe

- SS 317 Pipes Manufacturer in Mumbai

- UNS S31700 Tubing

- ASTM A213 TP317L Stainless Steel Welded Tube

- ASME SA213 TP317 Stainless Steel Tubes

- UNS S31703 Tubing

- 317L Stainless Steel Rectangular pipe

- SS 317 Tube

- 317L Stainless Steel Polished Pipe

- 317L Stainless Steel Hydraulic Tubing

- Stainless Steel 317 Welded Pipe

- 317L Stainless Steel Boiler Tubes

- Stainless Steel 317L Pipe Suppliers in Mumbai

- 317 Stainless Steel Industrial Pipes

- SS 317L Tubes Suppliers in Mumbai

- Stainless Steel 317 Pipe Manufacturers in India

- 1.4449 Seamless Pipe

- 317L Stainless Steel Hollow Pipe

- ASME SA312 TP317 Stainless Steel Pipes

- Stainless Steel 1.4438 Thick Wall Pipe

- SS 317L Thick Wall Tube

- SS 317 Tubes Suppliers in India

317L SS Tubing Chemical Composition

| Grades | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

SS 317 Pipes Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |