Stainless steel is a popular material in manufacturing due to its excellent corrosion resistance, durability, and strength. Stainless steel 316, in particular, is a top pick for many applications due to its superior qualities. It's a versatile material with different grades, each suitable for varying applications.

Stainless Steel 316 Reducing Tee, Ss 316L End Pipe Cap, SS 316L Buttweld Fitting, Stainless Steel 316H Pipe Caps, Stainless Steel 316L Pipe Fittings, SS 316 End Pipe Cap Stockist, SS 316H Pipe Nipples, Stainless Steel 316H Stub End, Stainless Steel 316L Buttweld Pipe Fittings, 316 SS Pipe Fittings Manufacturers in India.

Stainless Steel 316 Pipe Fittings come in various forms, including elbows, tee, reducer, stub ends, caps, nipples, and flanges. Elbows are of two types: 90-degree and 45-degree. Depending on the application, they're used to change the flow direction in pipelines. Conversely, tees are used to distribute the flow into two or more directions, creating a "T" shape. Reducers are used when the pipeline needs to change its size, either increasing or decreasing it from pipe to pipe. Stub ends offer a rotating guide to flanges, while caps are used to close the end of the pipeline.

Stainless Steel 316L Welded Pipe Fittings, Stainless Steel 316L Seamless Pipe Fittings, Stainless Steel 316H Pipe Fittings, Stainless Steel 316L Buttweld Tee, SS 316L Lateral Tee, SS 316H Cross, SS 316 Weldable Pipe Fittings, SS 316 Pipe Fittings Suppliers in India.

Stainless Steel 316L Pipe Fittings are the low-carbon version of stainless steel 316. They have excellent welding qualities and are preferred in welding applications due to their reduced susceptibility to carbide precipitation. In the pharmaceutical and cosmetic industry, stainless steel 316L pipe fittings are used because they don't corrode even with highly acidic chemicals, making them the perfect fit for producing drugs and other medications. Additionally, 316L pipe fittings are widely used in food processing facilities because they're hygienic and safe.

The high carbon content of Stainless Steel 316H Pipe Fittings makes them suitable for high-temperature applications. They exhibit excellent creep resistance and are ideal for use in extreme conditions where temperatures go beyond 500 degrees Celsius. This grade of pipe fittings is suitable for petrochemical plants, where coping with high pressure and temperature is necessary.

Stainless steel 316 pipe fittings offer numerous benefits, making them the go-to for many industries. For starters, they have excellent corrosion resistance capabilities, making them ideal for use in harsh environments that may be corrosive. Additionally, they're durable and easy to maintain, making them a sustainable option for many industries. They offer high strength, allowing them to withstand high pressure, temperature, and tension.

Stainless steel 316/316L/316H pipe fittings are an excellent choice for various applications in industries such as pharmaceutical, food, and petrochemical. Their durability, strength, and corrosion resistance make them an ideal and reliable option.

316 Stainless Steel Pipe Fittings Specifications

| Specifications | ASTM A403 / ASME SA403 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Type | DN15-DN1200 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Stainless Steel Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Connection | Welding |

| Manufacturing process | Forge, Cast, Push, Press, etc. |

| Key markets and industries |

|

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized manufacturer of | 90 Deg Elbows, 45 Deg Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End, Pipe Bend |

SS 316 Pipe Fittings Price List

| Price List of Stainless Steel 316 Pipe Fittings | SS 316 Pipe Fittings Price in India (INR) | SS 316L Pipe Fittings Price in USD | SS 316H Pipe Fittings Price in UAE (Dirham) |

|---|---|---|---|

| Price of Stainless Steel 316 90 Deg Elbow | ₹ 1317 | $ 24.78 USD | 76.30 AED |

| SS 316 Elbow Price List | ₹ 933 | $ 11.33 USD | 32.61 AED |

| Stainless Steel 316 Bend Price | ₹ 1560 | $ 13.82 USD | 53.11 AED |

| 316L Stainless Steel Weld Fittings Prices | ₹ 1497 | $ 17.00 USD | 65.44 AED |

| SS 316L Reducer Price Per Kg | ₹ 472 | $ 5.85 USD | 24.50 AED |

| SS 316 Elbow Price | ₹ 485 | $ 5.56 USD | 22.51 AED |

| SS 316 Pipe Fittings Price List | ₹ 2440 | $ 24.21 USD | 108.24 AED |

| Stainless Steel 316H 45 Degree Elbow Price | ₹ 5700 | $ 67.17 USD | 257.30 AED |

Stainless Steel 316 Buttweld Fittings Technical Data Sheet

Stainless Steel 316L Buttweld Pipe Fittings Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4401 | S31609 | - | - | - | - | - |

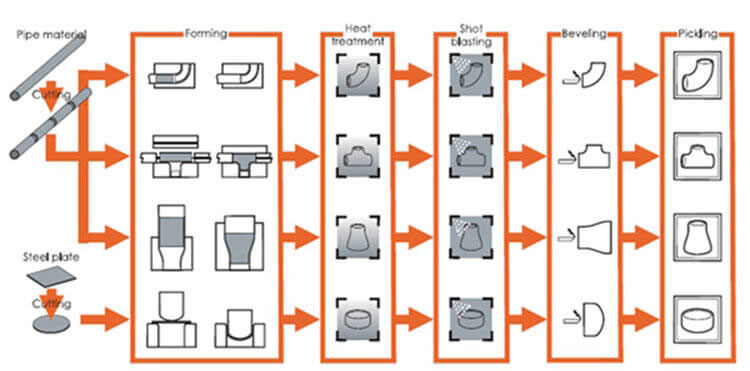

316L Stainless Steel Pipe Fittings Manufacturing Process

Common Types Of Stainless Steel 316 Pipe Fittings

316 Stainless Steel Elbow

316 Stainless Steel Reducer

Stainless Steel 316L Tee

SS 316H Cross

316L Stainless Steel Stub End

316H Stainless Steel Cap

316 Stainless Steel Pipe Bend

SS 316L Pipe Nipples

SS 316H Lateral Tee

Other Type 316 Stainless Steel Pipe Fittings

- Stainless Steel 316L Welded Pipe Fittings

- Stainless Steel 316L 45 Degree Elbow

- SS 316 Pipe Fittings Manufacturers in India

- Stainless Steel 316L Buttweld Pipe Fittings

- SS 316 Fittings Manufacturer in Mumbai

- Stainless Steel 316L Short Radius Elbow

- SS 316 Pipe Fittings Manufacturers in Mumbai

- UNS S31600 Pipe Fittings

- ASTM A403 Stainless Steel 316 Pipe Fittings

- Stainless Steel 316 180 Degree Elbows

- Stainless Steel 316 Pipe Fittings Suppliers in India

- Stainless Steel 316H Buttweld Tee

- 316 Stainless Steel Long Radius Elbow

- Stainless Steel 316H Seamless Pipe Fittings

- Stainless Steel 316H Welded Pipe Fittings

- Stainless Steel 1.4401 Welded Fittings

- SS 316L Pipe Fittings Suppliers in Mumbai

- 1.4404 Eccentric Reducer

- UNS S31609 End Pipe Cap

- 316 Stainless Steel Industrial Pipe Fittings

- SS 316 Pipe Fittings Suppliers in India

- Stainless Steel 316 Pipe Fittings Manufacturers in India

- SS 316H Concentric Reducer

- UNS S31603 Seamless Fittings

- Stainless Steel 316L Pipe Fittings Suppliers in Mumbai

- SS 316H Reducing Tee

- Stainless Steel 1.4401 Two Joint Pipe Fittings

- Stainless Steel 316L 3D Elbow

- ASME SA403 WP316 Stainless Steel Pipe Fittings

- ANSI B16.9 SS 316 Two Joint Pipe Fittings

316H SS Buttweld Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 11.00 - 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.89 min |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.89 min |

SS 316 Pipe Fittings Mechanical Properties

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 316 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 316L | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 316H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |