Nickel 200 is a commercially pure wrought nickel with excellent resistance to various corrosive environments, including reducing and oxidizing media. Its high corrosion resistance makes it an ideal material for manufacturing flanges. Nickel 200 flanges are widely used in various industries such as chemical processing, oil and gas, petrochemical, and pharmaceutical.

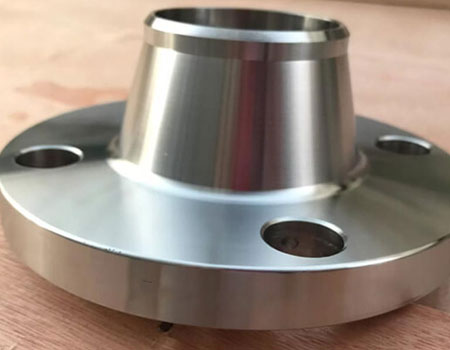

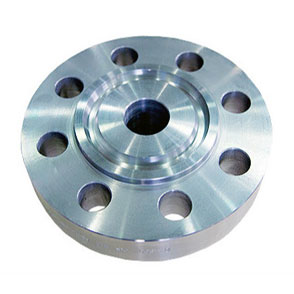

Nickel 200 flanges come in different types, including welding neck, slip-on, socket-weld, threaded, and blind flanges. The choice of flange type depends on the specific application. For instance, welding neck and slip-on flanges are ideal for high-pressure applications, while socket-weld flanges are suitable for small-bore lines. Threaded flanges, however, are ideal for low-pressure applications, and blind flanges seal off the end of a pipe.

Nickel 200 Flange Dimensions, Nickel Alloy 200 Slip On Flange, Nickel Alloy 200 Socket Weld Flange, Nickel Alloy 200 Blind Flange, Nickel Alloy 200 Welding Neck Flange, Nickel Alloy 200 Nipolet Flange Manufacturers in India.

Nickel 200 flanges have a wide range of applications due to their resistance to corrosion and temperature. They are used in various types of pipes in industries such as chemical processing, oil and gas, petrochemical, and pharmaceuticals. They are also used in heat exchangers, condensers, and pressure vessels. Nickel 200 flanges are used in applications that require resistance to corrosive environments, such as marine, chemical, and process industries.

Nickel 200 Puddle Flanges, Nickel 200 Socket Weld Flanges, Nickel 200 Lap Joint Flanges, nickel 200 Weldo flange, Nickel 200 Spectacle Blind Flanges, Nickel 200 Forged Flanges Manufacturers in India.

Nickel 200 flanges have numerous uses because of their excellent corrosion resistance properties. They are used in chemical industries for handling harsh chemicals and acids such as sulfuric acid, nitric acid, and hydrochloric acid. They are also used to manufacture fertilizers, dyes, and petrochemicals. In the oil and gas industry, Nickel 200 flanges are used to refine and process crude oil and natural gas. In the food industry, Nickel 200 flanges are used for handling food products and ensuring hygienic production processes.

Nickel 200 flanges offer several benefits compared to other materials. Their high corrosion resistance properties make them ideal for harsh environments, reducing maintenance costs and downtime. They also offer excellent thermal conductivity and high-strength properties, making them suitable for high-temperature and pressure applications. Additionally, Nickel 200 flanges are easy to machine and weld, making them easy to install and maintain in various applications.

Nickel 200 flanges have excellent resistance to various corrosive environments, making them ideal materials for various industries. They come in different types, such as welding neck, slip-on, socket-weld, threaded, and blind flanges, to cater to different applications. Nickel 200 flanges offer several benefits over other materials, reducing maintenance costs and downtime in applications that require resistance to harsh environments.

Nickel 200 Flanges Specification

| Standard | ASTM B564 / ASME SB564 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flange Size Chart | 1/2" (15 NB) to 48" (1200NB), DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Flange Connection / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove, Flange Pipe. |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Types of Flanges | Threaded / Screwed / Forged / Plate |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Test Of Flange | Direct-reading Spectrograph, Ultrasonic flaw detector, Magnetic particle detector, X-ray detector, Hydrostatic testing machine. |

| Production technique Used | Heat treated, Forged and Machined |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc. |

| Test Certificates | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc |

Nickel 200 Flange Price List

| Price List of Nickel 200 Flanges | Nickel Alloy 200 Flange Price in India (INR) | Nickel 200 Flanges Price in USD | Nickel Alloy 200 Flanges Price in UAE (Dirham) |

|---|---|---|---|

| Nickel Alloy 200 Flange Price Per Kg | ₹ 1050 | $ 17.69 USD | 53.02 AED |

| Nickel Alloy 200 Flange Price List India | ₹ 1754 | $ 35.50 USD | 152.00 AED |

| Nickel Alloy 200 Flanges Price List | ₹ 1474 | $ 27.60 USD | 75.50 AED |

| Price of Nickel 200 Flanges | ₹ 1890 | $ 12.78 USD | 60.50 AED |

| Nickel Alloy 200 Flanges Price | ₹ 900 | $ 16.24 USD | 29.50 AED |

| Alloy 200 Flange Price | ₹ 1624 | $ 15.59 USD | 60.52 AED |

| Nickel Alloy 200 Raised Face Blind Flange | ₹ 1172 | $ 11.53 USD | 41.17 AED |

| Nickel 200 Threaded Flanges Price | ₹ 1368 | $ 17.62 USD | 50.60 AED |

Nickel 200 Flanges Technical Data Sheet

Nickel 200 Pipe Flanges Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

Nickel Alloy 200 Flanges Manufacturing Process

Common Types Of Nickel 200 Flanges

Nickel Alloy 200 Weld Neck Flanges

Alloy 200 Blind Flanges

UNS N02200 Socket Weld Flanges

Nickel Alloy 200 Slip-on Flanges

Nickel 200 RTJ Flange

Nickel Alloy 200 Forged Flanges

Alloy 200 Lap Joint Flanges

Nickel Alloy 200 Threaded Flanges

Nickel Alloy 200 Spectacle Blind Flange

Other Type Nickel Alloy 200 Flanges

- Alloy 200 Flat Flange

- Alloy 200 Reducing Flanges

- Nickel 200 Weld Neck Flanges

- UNS N02200 Long Weld Neck Flanges

- ASTM B564 Nickel Alloy 200 Plate Flange

- Nickel Alloy 200 Threaded Flanges

- Nickel 200 Flat Face Flange

- Nickel 200 Flanges Suppliers in India

- Nickel Alloy 200 Flanges Manufacturer in Mumbai

- Nickel Alloy 2.4816 Raised Face Flanges

- Nickel Alloy 200 Socket weld Flanges

- UNS N02200 Flanges

- Nickel 200 Lap Joint Flanges

- Alloy 200 Forged Flanges

- Alloy 200 Square Flanges

- Nickel 200 Square Flanges

- Nickel 200 Socket Weld Flanges

- Nickel Alloy 200 Flange Dimensions

- Nickel Alloy 200 Flanges Manufacturers in India

- Nickel 200 Flanges Suppliers in Mumbai

- Nickel Alloy 200 Slip on Flanges

- ASME SB564 Nickel Alloy 200 Pipe Flange

- Nickel 200 Flanges Manufacturers in India

- Alloy 200 Orifice Flanges

- Nickel Alloy 200 Reducing Flanges

- UNS N02200 Plate Flanges

- Nickel Alloy 200 Lapped Joint Flanges

- Nickel Alloy 200 Flange Suppliers in India

- Alloy 200 Ring Type Joint Flanges

- Nickel 200 BS 4504 Flanges

- Nickel Alloy 200 Pipe Flanges

- Nickel 2.4816 Plate Flanges

- Nickel Alloy 200 Flanges Suppliers in Mumbai

- Nickel Alloy 200 Orifice Flanges

- 2.4816 Pipe Flanges

- Nickel Alloy 200 Industrial Flanges

- B564 UNS N02200 Blind Flanges

- ANSI B16.5 Alloy 200 Pipe Flanges

Nickel Alloy 200 Flanges Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Nickel Alloy 200 Flange Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |